The evolving role of software in supply chain management

The Transformative Influence of Software in Supply Chain Management

In today's rapidly evolving market landscape, the role of software in supply chain management has become increasingly pivotal. As consumer packaged goods (CPG) companies strive to meet the ever-changing demands of the market, software solutions are reshaping how these businesses operate. The integration of advanced analytics and real-time data processing is enabling more efficient chain planning and decision-making processes.

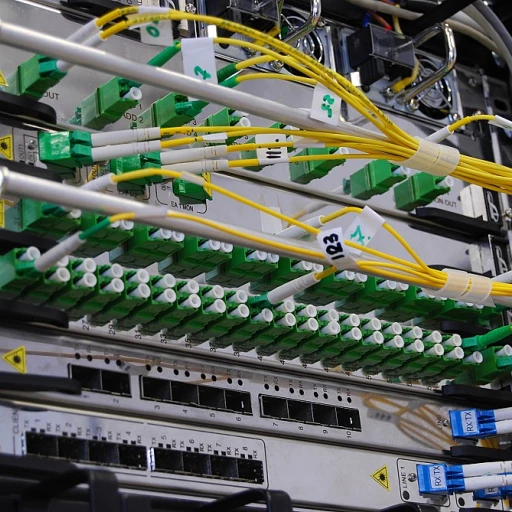

Supply chains are no longer just about moving products from point A to point B. They have evolved into complex networks that require sophisticated management tools to optimize every aspect of the chain model. From inventory management to product development, software is at the heart of these operations, providing CPG companies with the tools they need to enhance their operating models and improve overall efficiency.

One of the key benefits of leveraging software in supply chain management is the ability to respond swiftly to market changes. With real-time data, companies can adjust their production and inventory levels to align with consumer demand, minimizing waste and maximizing profitability. This agility is crucial for maintaining a competitive edge in the fast-paced world of consumer goods.

Moreover, software-driven supply chain optimization is not just about immediate gains. It also supports long-term strategic planning by providing insights into trends and patterns that can inform future business decisions. As CPG companies continue to navigate the complexities of global supply chains, the importance of robust software solutions will only grow.

For more insights into how businesses are adapting to the software-driven future, you can explore this resource.

Key challenges in CPG supply chain organization design

Addressing the Complexities of Supply Chain Design

Designing a consumer packaged goods (CPG) supply chain organization involves navigating a labyrinth of challenges. As companies strive to meet the ever-evolving demands of the market, they must address several key issues that can hinder their efficiency and effectiveness.

Balancing Demand and Supply

One of the primary challenges in CPG supply chain management is balancing demand with supply. Companies must accurately forecast demand to ensure they have the right amount of inventory at the right time. This requires sophisticated chain planning and advanced analytics to predict consumer behavior and market trends. Without precise demand forecasting, businesses risk either overproduction, leading to excess inventory, or underproduction, resulting in stockouts and lost sales.

Optimizing Inventory Management

Effective inventory management is crucial for CPG companies. The ability to manage raw materials and finished products efficiently can significantly impact a company's bottom line. Companies need to develop a robust operating model that allows for real-time data analysis and decision making. This helps in minimizing holding costs while ensuring product availability across the supply chain.

Streamlining Production Processes

Production processes in CPG supply chains must be streamlined to reduce time and cost. Companies face the challenge of integrating new technologies and processes that can enhance production efficiency. This involves adopting innovative software solutions that facilitate seamless communication and coordination across different stages of the supply chain.

Adapting to Market Dynamics

The dynamic nature of the consumer goods market requires CPG companies to be agile and responsive. This means continuously adapting their supply chain model to accommodate changes in consumer preferences, regulatory requirements, and competitive pressures. Companies must invest in data-driven decision making to stay ahead in the competitive landscape.

For more insights on enhancing efficiency in CPG supply chain networks, you can explore our detailed analysis here.

Innovative software solutions for supply chain optimization

Revolutionizing Supply Chain Operations with Cutting-Edge Software

In the ever-evolving landscape of consumer packaged goods (CPG), companies are increasingly turning to innovative software solutions to optimize their supply chain operations. These advancements are not just about keeping pace with demand but are crucial for maintaining a competitive edge in the market. As CPG companies strive to enhance their supply chain management, they are leveraging technology to streamline processes, reduce costs, and improve efficiency.

One of the key areas where software is making a significant impact is in chain planning. Advanced analytics and real-time data integration allow businesses to make informed decisions quickly, adapting to market fluctuations and consumer demands with agility. This dynamic approach to supply chain management ensures that companies can respond to changes in the market without compromising on product availability or quality.

Harnessing Data for Strategic Decision Making

Data-driven decision making is at the heart of modern supply chain optimization. By utilizing sophisticated software tools, CPG companies can analyze vast amounts of data to forecast demand, manage inventory, and optimize production schedules. This not only helps in reducing waste and lowering costs but also ensures that consumer goods are delivered on time, enhancing customer satisfaction.

Moreover, the integration of software solutions in supply chain processes facilitates better communication and collaboration across different departments. This seamless flow of information enables a more cohesive operating model, where every aspect of the supply chain—from raw materials to finished products—is aligned with the company's strategic goals.

Automation: A Game Changer in Supply Chain Efficiency

Automation is another critical component of supply chain optimization. By automating routine tasks, companies can free up valuable time and resources, allowing them to focus on more strategic initiatives. This shift not only improves operational efficiency but also enhances the overall productivity of the supply chain.

As CPG companies continue to explore new ways to optimize their supply chains, the role of software will undoubtedly become even more pivotal. With the right tools and technologies, businesses can create a resilient and responsive supply chain that meets the demands of today's fast-paced consumer market.

Data-driven decision making in supply chain design

Leveraging Data for Strategic Decisions

In the rapidly evolving landscape of consumer packaged goods (CPG) supply chains, data-driven decision making has become a cornerstone of effective chain management. Companies are increasingly relying on advanced analytics to transform raw data into actionable insights, enabling more informed decisions across various stages of the supply chain. This shift is not just about collecting data but about using it strategically to optimize processes and enhance efficiency.

Real-Time Insights for Better Planning

One of the key advantages of data-driven decision making is the ability to access real-time insights. This capability allows CPG companies to respond swiftly to market changes, adjust inventory levels, and refine production schedules. By integrating real-time data into their chain planning, businesses can better anticipate demand fluctuations and align their supply chain model accordingly. This proactive approach helps in minimizing waste and ensuring that consumer products are available when and where they are needed.

Enhancing the Operating Model with Data

Data-driven strategies also play a crucial role in refining the operating model of CPG supply chains. By analyzing consumer behavior and market trends, companies can make informed decisions about product development and distribution. This approach not only supports long-term planning but also enhances the agility of supply chains, allowing them to adapt to changing consumer demands and business environments.

Challenges and Opportunities

While the benefits of data-driven decision making are clear, there are challenges that CPG companies must navigate. Ensuring data accuracy, integrating disparate data sources, and maintaining data security are critical concerns. However, the opportunities for chain optimization through effective data management are immense. By investing in robust data analytics tools and fostering a culture of data literacy, companies can unlock significant value from their supply chains.

The impact of automation on supply chain efficiency

Automation: A Catalyst for Efficiency

In the realm of consumer packaged goods (CPG) supply chains, automation is emerging as a pivotal force driving efficiency. As companies strive to enhance their supply chain management, automation offers a transformative approach to streamline processes, reduce errors, and optimize resource allocation. The integration of automated systems within supply chains enables CPG companies to respond swiftly to market demands, ensuring that consumer products are delivered in a timely manner.

Automation in supply chain management is not just about replacing manual tasks with machines. It involves the strategic implementation of advanced technologies that can handle complex tasks such as inventory management, demand forecasting, and production planning. By leveraging automation, CPG companies can achieve a more agile and responsive supply chain model, which is crucial in today's fast-paced market environment.

Enhancing Decision Making with Real-Time Data

One of the significant benefits of automation is its ability to facilitate data-driven decision making. Automated systems can process vast amounts of data in real time, providing valuable insights that help companies make informed decisions. This capability is particularly beneficial for chain planning and product development, where timely and accurate data is essential for optimizing production schedules and managing raw materials efficiently.

Moreover, automation supports the implementation of advanced analytics, allowing CPG companies to predict consumer demand more accurately and adjust their operating models accordingly. This proactive approach not only enhances supply chain efficiency but also contributes to long-term business sustainability.

Challenges and Opportunities

While the benefits of automation are clear, CPG companies must also navigate several challenges. The initial investment in automated systems can be substantial, and there is a need for skilled personnel to manage and maintain these technologies. However, the long-term gains in efficiency and productivity often outweigh these initial hurdles.

As automation continues to evolve, CPG companies have the opportunity to redefine their supply chain processes, creating more resilient and adaptable chains. By embracing automation, businesses can not only improve their current operations but also position themselves for future growth in the competitive consumer goods market.

Future trends in CPG supply chain software

Embracing Advanced Analytics and AI

As consumer packaged goods (CPG) companies look to the future, the integration of advanced analytics and artificial intelligence (AI) into supply chain management is becoming increasingly critical. These technologies enable real-time data analysis, allowing businesses to make informed decisions quickly. By leveraging AI, CPG companies can enhance their demand forecasting, optimize inventory levels, and streamline production processes. This shift towards data-driven decision making is transforming how supply chains operate, making them more efficient and responsive to market demands.

Enhancing Flexibility with Cloud-Based Solutions

Cloud-based solutions are revolutionizing supply chain management by providing flexibility and scalability. These platforms allow CPG companies to adapt their supply chain models in response to changing consumer demands and market conditions. With cloud technology, businesses can manage their supply chains more effectively, ensuring that raw materials and products are available when needed. This flexibility is crucial for maintaining a competitive edge in the fast-paced consumer goods market.

Automation: A Key Driver of Efficiency

Automation is set to play a pivotal role in the future of CPG supply chains. By automating routine tasks, companies can reduce errors, lower costs, and improve overall efficiency. Automation technologies, such as robotic process automation (RPA) and autonomous vehicles, are being integrated into supply chain operations to enhance productivity. As automation continues to evolve, it will enable CPG companies to focus on strategic planning and product development, rather than being bogged down by manual processes.

Building Resilient Supply Chains

In an era of uncertainty, building resilient supply chains is more important than ever. CPG companies are investing in technologies that enhance their ability to respond to disruptions, whether they stem from natural disasters, geopolitical tensions, or shifts in consumer behavior. By adopting a proactive approach to risk management, businesses can ensure continuity and maintain their competitive advantage in the long term.

Collaborative Ecosystems for Innovation

The future of CPG supply chains will also be shaped by collaborative ecosystems that foster innovation. By partnering with technology providers, logistics companies, and other stakeholders, CPG companies can develop innovative solutions that address complex supply chain challenges. These collaborations are essential for driving chain optimization and ensuring that supply chains remain agile and efficient in the face of evolving market demands.

-large-teaser.webp)